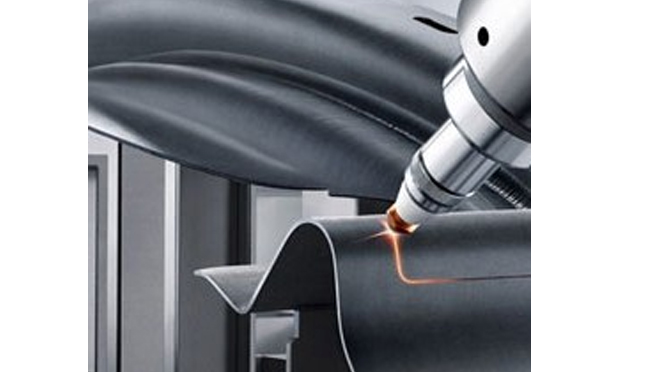

(Photo courtesy of GF Laser)

The automotive industry is one of the largest users of laser cutting worldwide. Most large car companies operate their own lasers as well as outsourcing to specialist laser cutting sub-contractors.

The reasons for this continued growth are discussed below:

DECREASE PROTOTYPE TO PRODUCTION TIMESCALES

Automotive companies pour millions of pounds into developing new models to drive sales. It’s vital that they see a return from their investment as soon as possible. Utilising laser cutting at the prototype phase means that changes can be made quickly and easily without the need to change hard tooling. Quick and easy means the car ultimately gets to market faster so that the automotive companies can start recouping there investment as soon as possible.

MEETING CUSTOMER DEMAND FOR MODEL VARIATIONS

The famous words attributed to Henry Ford: “You can have any colour as long as it’s black” are a distance memory for most carmakers. Interestingly, Ford uttered this line to his salespeople as he was afraid they were trying to cater to the minority of customers who wanted slightly different variants rather than the majority that were happy with the standard vehicle. Customers now have a myriad of choices and variants when they buy a new vehicle. This presents manufacturing with an issue as Production lines work better when every part or vehicle is produced in an identical fashion. Exactly the problem that Ford was trying to alleviate.

Laser cutting helps solve the problems associated with offering different variants. How? Well manufacturers can develop a standard chassis but then use laser cutting to put in an extra hole where required to help cater for a model change. In addition, because laser cutting suits low volume automotive production then components can be laser cut rather than using expensive tooling. So, car companies can launch a model variant that caters for a smaller segment of customers without risking hundreds of thousands of pounds in tooling for a model that may only sell in thousands rather than millions.

REDUCING WEIGHT

The automotive industry has long been under pressure to reduce emissions and improve fuel economy. To do this the industry has been developing vehicles using metals that are lightweight thus using less fuel and omitting less pollution.

However, the problem with lighter metals, now used in making cars, is that they do not perform well when cut using traditional trim tools. The panels tend to distort and spring rendering them unfit for purpose.

Ironically perhaps, in light of recent allegations, Volkswagen were the first automotive company to solve this issue. They used specialist 5 axis laser cutting technology to cut the panels and productionised the process using robots and utilising subcontractors to meet peaks in demand.

The 5 axis laser meant that holes and apertures could be cut without pressing so solving the issue of deformation.