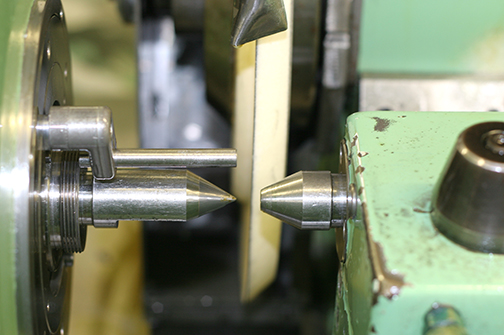

Oregon State University has been chosen for one of the first seven grants from the Walmart U.S. Manufacturing Innovation Fund created by Walmart and The Walmart Foundation to help accelerate manufacturing in the United States. The $590,000 grant will support the development of innovations in plastics injection molding – one of the most common manufacturing processes for making consumer products – in which melted plastic resins are injected into a shaped cavity made by two metallic molds.

“Current practices for fabricating these molds are labor-intensive and costly, and much of the mold material is wasted as metal chips,” said Sundar V. Atre, OSU associate professor of industrial and manufacturing engineering. “We estimate that mold-making costs can be reduced by 40 to 50 percent.”

“That will give U.S. manufacturing an edge,” Atre added.

The Walmart U.S. Manufacturing Innovation Fund, in collaboration with the Conference of Mayors, will provide a total of $10 million in grants over the next five years. The first $4 million in grants were announced Thursday (Aug. 14) at the 2014 U.S. Manufacturing Summit in Denver.

“Researchers at many of America’s best universities are hard at work on tough manufacturing challenges,” said Kathleen McLaughlin, president of The Walmart Foundation. “We are excited to support the development of innovative solutions, which we hope will unlock new opportunity for manufacturing in this country.”

Mayor Julie Manning of Corvallis noted that her city has earned a national reputation for innovation, ranking fourth last year in a report of patents per capita.

“A manufacturing renaissance is taking place in our region,” she said. “This project builds on the steps taken in recent years to more closely align the economic development strategy of Corvallis and Benton County with the growing success of Oregon State University and other local employers in fostering innovation and job creation.”

Over the course of the three-year project, Atre and his co-principal investigator, Oregon State mechanical engineering assistant professor Rajiv Malhotra, will work with three industrial partners – Metal Technology, Inc., in neighboring Albany, Ore., plus Arburg and North American Höganäs – to develop and test their manufacturing innovations. Part of the work will take place at the Microproducts Breakthrough Institute, collaboratively managed by OSU and the Pacific Northwest National Laboratory.

The team will work with the OSU Advantage Accelerator to develop a commercialization plan. This program helps move promising ideas out of the laboratory and into the marketplace, strengthening the economy.

Atre’s and Malhotra’s project is a prime example of the university’s leading-edge research that creates a better future for Oregon and the nation, said Robert B. Stone, head of OSU’s School of Mechanical, Industrial, and Manufacturing Engineering.

“Making U.S. manufacturing more competitive globally is something all of us can relate to,” Stone said. “When we shop, we know the ‘Made in the USA’ label signifies jobs and stronger communities. This support from Walmart, The Walmart Foundation and the Conference of Mayors represents a vote of confidence in our track record at Oregon State of doing research with real-world impact, as we work in partnership with industry.”

In 2010 alone the U.S. plastics industry produced an estimated 16 billion pounds of injection-molded products for applications in packaging, electronics, housewares and biomedical areas.

The grant to Oregon State is part of The Campaign for OSU, which has raised more than $1.06 billion to support university priorities, including more than $140 million in private faculty research grants. The university community will celebrate the campaign’s impact Oct. 31 during Homecoming.