In the dynamic world of additive manufacturing, 3D printing has transcended its initial novelty status to become a pivotal component of industrial, medical, and consumer applications. As we navigate through the technological advancements and innovative practices shaping the future, several key trends and future technologies are emerging within the 3D printing landscape.

These developments promise to revolutionise the way we design, produce, and conceptualise the role of manufacturing in our lives. Furthermore, for enthusiasts and professionals alike, the quest for quality 3D filament in Australia is becoming easier, thanks to dedicated suppliers committed to enhancing the 3D printing experience.

Sustainable Materials and Eco-Friendly Printing

Sustainability is a driving force in the evolution of 3D printing materials. The industry is witnessing a significant shift towards the use of eco-friendly filaments, such as biodegradable plastics and recycled materials. These sustainable options not only minimise environmental impact but also open up new possibilities for waste reduction and circular economy practices within manufacturing processes.

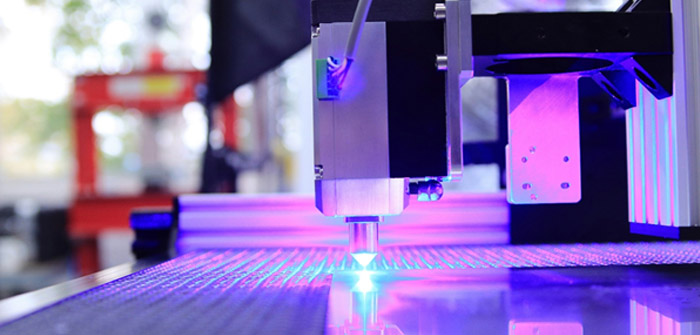

Advanced Composite and Functional Materials

The exploration of composite materials, incorporating carbon fibre, glass, and conductive additives, is expanding the capabilities of 3D printed objects. These materials enhance the strength, durability, and functionality of prints, enabling the creation of parts that are lighter, more resilient, and capable of conducting electricity or withstanding extreme temperatures.

Customisation and Personalisation at Scale

3D printing is at the forefront of the bespoke manufacturing movement, offering unparalleled customisation options for individual consumers and industries alike. From personalised medical implants and prosthetics to tailor-made automotive and aerospace components, the ability to design and produce items that fit specific requirements and preferences is transforming traditional manufacturing paradigms.

Integration of AI and Machine Learning

Artificial intelligence (AI) and machine learning are becoming integral to optimising 3D printing processes, from design and material selection to print optimisation and quality control. AI algorithms can predict and adjust printing parameters in real-time, reducing waste, improving accuracy, and enabling the autonomous correction of errors during the printing process.

Expansion of 4D Printing

While 3D printing creates static objects, 4D printing introduces the dimension of time, with materials that can change shape or properties in response to external stimuli such as temperature, light, or moisture. This emerging field promises groundbreaking applications in areas ranging from biomedical devices and wearable technology to infrastructure and environmental monitoring.

Increased Accessibility and Education

As 3D printing technology becomes more accessible and affordable, its integration into educational curricula and hobbyist projects continues to grow. This democratisation is fostering a new generation of designers, engineers, and innovators equipped with the skills to harness the potential of additive manufacturing.

The future of 3D printing is bright, with emerging trends and technologies paving the way for more sustainable, efficient, and customisable manufacturing solutions.