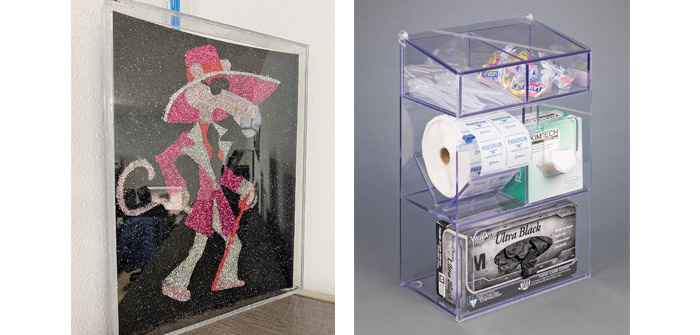

((L)The Pink Panther masterpiece that started the Poltex path (R) Medical Supplies Organizer by Poltex | Photos courtesy of Poltex)

Ever wondered where those oft-unnoticed medical office organizing accessories such as clear magazine racks, sanitizer holders or face-covering dispensers come from? Chances are it could be a product of innovative Redmond-based plastic fabrication specialists Poltex.

Under the guidance of owner Paul Filipowicz, since moving to Redmond in 2014 the company has expanded from 2,000 square feet to over 10,000 square feet, producing a continually expanding variety of items, primarily aimed at laboratory and hospital workplaces.

Filipowicz says it all started with a glitter-glue sketch of his cartoon favorite the Pink Panther from then-girlfriend (now wife) Danielle. He wanted to “present it like the Mona Lisa,” sketched a design, bought some materials and built a special display case in his garage to show off the masterpiece.

Building on his scientific background in molecular genetics, he had the brainwave of using similar techniques to improve his work environment operations.

He recollected, “I was working for Kaiser-Permanente at the time, and I felt like I needed three hands to get everything done.

“I have always been a highly organized person who believes that ‘there’s a place for everything and everything in its place,’ so I began to build plastic containers, shelves and stands for work.

“I realized there was a real need for these types of plastic and polycarbonate products — that looked great, saved space and improved efficiency and production in those work environments — so I taught myself some basic Computer-Aided Design (CAD) skills and basically launched Poltex out of my garage.

“My family also had a background in milling and machining, so together with the science grounding it gave me a good general foundation to build from.”

His initial products quickly gained in popularity, leading to him to strike out on his own in 2001, and since then Poltex has continued to turn out a steady stream of standard and custom-fabricated products, including a recent point-of-purchase display for Redmond lithium battery pioneers Expion 360.

Business has grown exponentially over the past two decades and today the product line includes around 650 *SKU’s. (*SKU stands for “stock keeping unit” and is a number that retailers use to differentiate products and track inventory levels. Products are assigned different alphanumeric digits based on various characteristics, such as price, manufacturer, color, style, type and size).

Filipowicz added, “We have two product streams — custom pieces and standard pieces. Basically, every product we make starts as a custom piece.

“We save all our designs and if something can be used by multiple clients then it becomes part of our standard product line — if something is living digitally, it can be reproduced.

“We start with a CAD program and design a picture of the product. We then send that to the client to verify that the piece meets all their needs.

“Once the design is approved, we create the 3D model that is sent to our CNC (Computer Numerical Control) machine. This machine cuts the product according to the automated instructions so we can build it and ultimately, deliver it to our client.

“What really sets Poltex apart is our ability to provide our laboratory and healthcare customers with organizational equipment that suits the exact needs of their work environment.

“Because we manufacture all our products in-house, right here in the U.S., we are able to produce affordable products with a quick turnaround time to suit the exact specifications of the particular space, consumable, project, etc. Poltex is proud to make all products in-house with the stamp of Made in the USA and does not have any plans to outsource.

“We can customize and build pretty much anything, with a rapid sequence from prototype to production. We take ideas and make them a reality in an easy and affordable process, including free design services.

“Custom work keeps things fresh and regularly producing quality innovative products allows us to keep a pulse on the market.”

Filipowicz said business actually spiked during COVID, and the standard side of operations was up 38 percent over last year. The growth curve has continued, including negotiating more retail contracts and recently picking up distribution with Grainger, a leading provider of top-quality industrial supplies worldwide.

On the choice to grow in Redmond, he said, “Redmond is awesome. The business community is really tight-knit, and we have enjoyed the support and sense of community with other business owners and industry people here.

“Additionally, resources like REDI (Redmond Economic Development Inc.) are very supportive. EDCO was particularly helpful early on, and after being invited to participate in the “Made in Redmond” tour event, it helped us get a ‘foot in the door’ with local medical providers, including BMC (now Summit Health) and St. Charles Hospital. Recently we also added Mosaic Medical as a customer.”

On the horizon, Filipowicz sees increased business necessitating hiring additional employees and tooling up for increased production, including staying current with the latest technology to optimize manufacturing methods.

He added, “With the large swirl of impending business, we should continue to be growing pretty rapidly.

“Given the huge opportunities coming our way, we feel we have barely scratched the surface in the market, and believe the possibilities are endless.

“Nobody else is currently creating custom plastic fabrication products of this quality. There is a lot of potential and a lot of untapped markets that we can pursue.”

Though business is primarily in the U.S., Poltex has shipped internationally (Canada, Mexico, England) to some small extent. But Filipowicz says international shipping on an individual order basis is cost prohibitive.

In light of making all products in-house, expanding globally would likely happen incrementally, with the need to identify feasible distribution network logistics.

Expectations for the near future included negotiating with more large retail distributors, working on government contracts including Veterans Affairs facilities and increasing an online presence through channels like Amazon, Facebook, Instagram and YouTube.

poltex.com • 541-636-080