New Product Could Save Property Owners Thousands When Retrofitting Old Systems

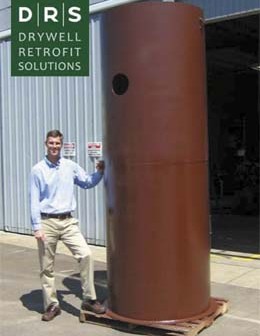

Grant Hardgave, founder of Drywell Retrofit Solutions based in Bend, has a patent pending on his newest invention: Drywell Retrofit Sump Insert.

Grant Hardgave, founder of Drywell Retrofit Solutions based in Bend, has a patent pending on his newest invention: Drywell Retrofit Sump Insert.

Hardgrave is a local civil engineer who has invented the sump insert to help commercial property owners and local municipalities save thousands of dollars as they retrofit old storm water drywells to meet current requirements.

On most commercial properties in Central Oregon, storm water from roof tops and paved areas is disposed of using drywells. “Local municipalities also use drywells to dispose of storm water from public roadways” explained Hardgave. “These underground drywells infiltrate the storm water into the native soil and rock where it eventually makes its way into the groundwater. Any pollutants that the storm water may have picked up as it flowed across the pavement surface are carried along into the groundwater where they can possibly contaminate drinking water supplies.”

The Oregon Department of Environmental Quality (DEQ) regulates drywells as part of the federal Safe Drinking Water Act (SDWA), which requires that all storm water drywells be operated in a manner that protects groundwater supplies. Under this program, DEQ grants authorization to drywell operators who comply with program requirements and issues enforcement actions against those who do not.

The SDWA has no “grandfather” clause and all drywells need to comply with current requirements, regardless of when they were constructed. The exact number is unknown, but it is estimated that there are at least 5,000 storm water drywells currently in use throughout Central Oregon.

As of January 2007, approximately 48,000 individual injection systems have been submitted for registration in Oregon. Of those only 50 percent meet state rule authorization requirements and are predominantly newer systems installed in the last six years. Currently about 40 percent of the registered stormwater systems are owned and operated by federal, state and local municipalities.

HOW IT WORKS

The Drywell Retrofit Sump Insert is installed inside an existing drywell and provides a simple, cost-effective method of pre-treating the storm water before it infiltrates into the soil and makes its way to the groundwater. This innovative product can save government agencies and private property owners thousands of dollars when retrofitting existing storm water drywells and is immediately available for delivery and installation throughout Oregon.

The Sump Insert saves money by minimizing the amount of excavation and repaving necessary to retrofit a typical drywell. Current methods require the removal and replacement of up to 60 square yards of pavement per drywell. The Sump Insert requires no more than 20 square yards of pavement replacement. Also, traditional methods require the excavation of a large hole, often hammered into the native rock, for installation of a treatment system. The Sump Insert is installed inside the void space of the existing drywell and eliminates the need for a separate costly excavation.

When the raw polluted storm water enters the Sump Insert, the sand, silt, and other heavier-than water particles settle out and are collected in the bottom of the sump. The oil, grease, and other lighter-than-water pollutants float on the surface and are kept inside the Sump Insert by the oil baffles on the two outlet ports. To maintain it, simply pump it out about once a year.

Hardgave adds that, “it’s economical to install and maintain, delivered to job site fully assembled and ready to drop into place, there’s no expensive filters to purchase and maintain and each unit can be custom fabricated for height & diameter of existing drywell.”

541-610-7366, sales@drywellretrofitsolutions.com, www.drywellretrofitsolutions.com.