Oregon had the majority of its grades drop in an annual report from Ball State University. At the same time The State of Oregon, through its economic development arm, Business Oregon, and in partnership with the State of Washington, has received a federal designation as one of 12 new communities under the Investing in Manufacturing Communities Partnership (IMCP) initiative (see related article this eblast).

The 2015 Manufacturing and Logistics Report, prepared by Ball State’s Center for Business and Economic Research (CBER) for Conexus Indiana, the state’s advanced manufacturing initiative, shows how each state ranks among its peers in several areas of the economy that underlie the success of manufacturing and logistics.

These specific measures include the health of the manufacturing and logistics industries, the state of human capital, the cost of worker benefits, diversification of the industries, state-level productivity and innovation, expected fiscal liability, the state tax climate, and global reach.

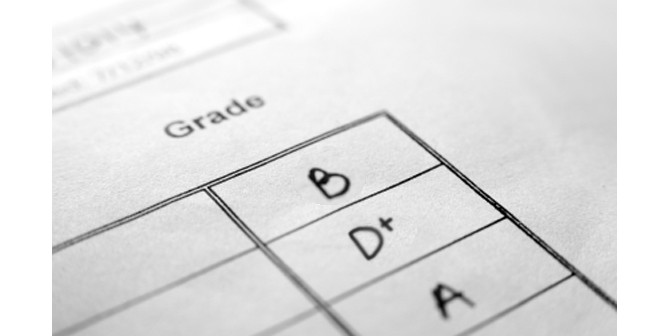

CBER director Michael Hicks says “It was a mixed year for Oregon, which saw its grades in manufacturing industry category drop from A to B, in logistics industry category from C to D+, in human capital category from C to C-, and in productivity and innovation category from A to B+. Oregon improved its grades in global position category from D- to C- and in expected fiscal liability gap from B to A.

Grades:

Manufacturing: B

Logistics: D+

Human Capital: C-

Worker Benefit Costs: C

Tax Climate: C

Expected Liability Gap: A

Global Reach: C-

Sector Diversification: F

Productivity and Innovation: B+

Hicks also provides an analysis of why the American’ manufacturing and logistics are in better shape than many believe in the companion study The Myth and the Reality of Manufacturing in America.

“There are major misunderstandings among the public and the media about the manufacturing sector,” he said. “The U.S. manufacturing base is not in decline, and we have recovered from the recession. Nor are jobs being outsourced because American manufacturing can’t compete internationally. Moreover new jobs in manufacturing pay well above the average wage.”

The study notes that the Great Recession had lost its stranglehold by 2014, when U.S. manufacturers attained record levels of production.

“Overall, only 13 percent of lost jobs over the past decade, which are less than 4 percent of all manufacturing jobs, can be linked to international trade and most of trade related job losses are in low productivity sectors,” Hicks said. “Changes in productivity, domestic demand and foreign trade all impact manufacturing employment in the U.S., and it’s important to clarify those impacts in order to understand what is happening in the manufacturing and logistics industries.”

Both reports are available at http://conexus.cberdata.org/