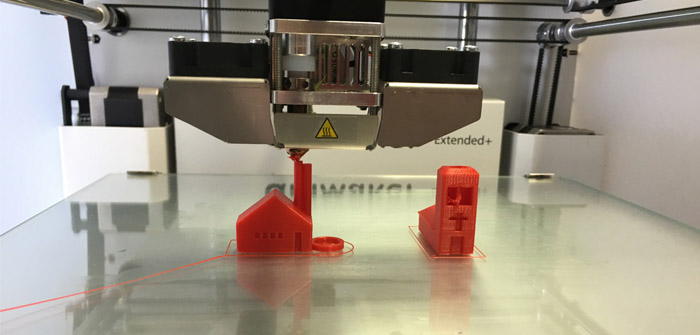

(Photo | Pixabay)

3D printing is one of the most intriguing tech trends which is still in the early stages of its evolution and impact. Today, 3D printers are printing buildings, walls, homes, musical instruments, jewelry, athletic shoes, clothing, plastic product prototypes, tools, airplane parts, body parts, car parts, food, prosthetics and many other items. They range in size from monster printers creating high-rise buildings by “printing” floors, to large, on-site printers creating houses and walls. On the other end of the spectrum are a wide variety of hobby printers about the size of a dorm fridge which can print small objects.

The current limitations are rapidly disappearing: speed, materials, cost and waste. Combining 3D printing with other exponential technologies such as robotics, AI and Machine Learning, 5G network technologies, vision and voice will create the next wave of massive innovation.

The Challenges

Speed — The speed of printing is rapidly increasing, making 3D printers more viable for mass production. The problem with increasing the speed is it creates stronger vibrations which affect the quality of the printed object. Researchers at the University of Michigan have created an algorithm which doubles the speed without affecting the quality.

Materials — Until recently, plastic has been the most common building material. Other materials include cement, bio-mass (for body parts), puréed food and resins.

Metal — The holy grail is to perfect metal printing. Current metal materials include aluminum, stainless steel, titanium, cobalt chrome and nickel alloys.Metal 3D printing is best for complex, custom parts which are costly and difficult, or impossible, to produce with traditional manufacturing methods.

Cost — Costs to produce simple items with 3D printers compared to traditional manufacturing are still too high. 3D printers do have the advantage when printing highly complex structures which, in some cases, can’t be produced using traditional methods. The same scaling costs seen in other products moving from low volume to high volume production apply here. The cost of materials and wastage will drop exponentially as the tech improves and volumes increase.

The Promise

Factories of the Future — Although 3D printing has been around since the 80’s, advancements have accelerated in the last five years. When 3D printing finally is mass-production capable, imagine the factory of the future. It most likely will be built in the USA due to minimal labor impact on production costs.

Robotics + AI + 3D Printing + 5G + autonomous vehicles — Robots operating 3D printers… the ultimate on-demand factory. Imagine placing an order on Amazon. Amazon prints your product to your exact measurements and finish. Robots manage the process, load the delivery truck and AI gives the autonomous truck the necessary directions to your location. A robot takes the package off the truck and deposits it on your doorstep.

Home Printing — In the not-too-distant future, 3D printers will be the new home appliance . Instead of paying for a new pan, you’ll pay for the 3D plan to download to your 3D printer. You’ll buy the cartridges just like you do for your inkjet printer and you’ll be able to mix and match the material cartridges as each plan requires. When a cartridge runs low, the 3D printer will automatically order replacements, just like HP printers do now.

Complex Objects — creating complex objects with intricate internal structures are either too costly or impossible to do with traditional marketing methods. 3D printers can, cost effectively.

My Take

Like many other disruptive, game-changing trends, 3D printing’s full potential won’t be fully realized until it’s combined with other exponential technologies such as hyper-local power generation and storage, smartphones, robotics, cloud-based infrastructure, AI and Machine Learning, 5G network technologies, vision and voice. Combine any two or more of these, and you have a unique solution-set which will have its own innovative, massively disruptive impact. Just like Einstein’s equations led to atomic power and the bomb, every new technology can be used for good or ill. You can 3D print a toy or a gun, it’s up to you to decide which one.

Preston Callicott is CEO of Five Talent Software, Inc. based in Bend, Oregon. His hope is that writing articles will allow his mind to stop waking him up at 4am with “aha’s” and “oh-my’s” about the massive impact tech has on our collective future.

Find Out More

3D Printing Trends: fabbaloo.com/blog/2018/12/26/these-trends-will-shape-3d-printing-moving-into-2019

U-M 3D Printing algorithm: news.umich.edu/3-d-printing-gets-a-turbo-boost-from-u-m-technology

Wikipedia—3D Printing: en.wikipedia.org/wiki/3D_printing

Intro to Metal Printing: 3dhubs.com/knowledge-base/introduction-metal-3d-printing

3D Printed Food: all3dp.com/1/3d-printed-food-3d-printing-food

Metal Casting—Adobe: autodesk.com/redshift/metal-casting-and-additive-manufacturing

Singularity University—Tech Trends 2019: su.org/blog/exponential-technology-trends-defined-2019