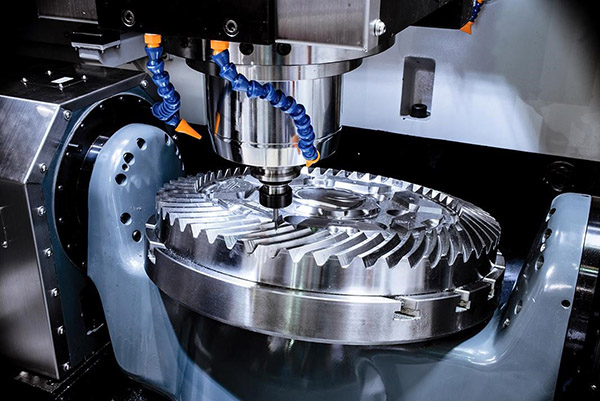

A computer numerical control (CNC) machine is a machine programmed to convert numerical code to cartesian coordinates with the purpose of transforming raw material into an end-product. CNC milling is a special type of CNC machining that utilizes automatic controls and a milling machine to gradually remove material from a solid block to create a part.

The milling machine is similar to some other drilling machines because it’s also intended to drill and cut materials. Nevertheless, CNC milling machines are different from standard drilling machines because they can move along different axes and cut at more angles. Basically, a milling machine can have an unlimited number of axes, but most of them are generally described as 3-axis, 4-axis, and 5-axis machines.

Photo from Industry Today

CNC milling is appropriate for countless materials, including metal, glass, wood, and plastic. Similar to the other CNC machining processes, milling depends on automatic computer controls to control the tools that cut and form the filling material.

Unlike most of the other CNC manufacturing methods, CNC milling is a mechanical procedure. That means that filling material is removed from the machine part through a mechanical process rather than an electrical, chemical, or thermal process.

So, keep on reading to find out more about this groundbreaking CNC manufacturing technique. Below, we guide you through the benefits of CNC milling that you can gain for your business if you start implementing this manufacturing method.

Lowers The Production Time And It Excludes The Chance For Error

When using a CNC milling machine, the multiple months period required to plan, design, and manufacture prototypes is entirely eradicated. On the other hand, the amount of time spent on the inspection process is also eliminated when using CNC milling machines. All you need to do is inspect the initial part produced by the CNC milling machine, and after the initial part, all the following produced parts will be a 100% perfect replica of the first one.

Additionally, CNC milling machines are fully controlled by computer controls, and that’s why zero errors will happen during the process. The work task of the machine operator is just to enter some digital computer orders and directions inside the machine’s controller. Afterward, its settings will work according to the given instructions. It excludes the chance of both machine and operator error. Plus, it also results in a reduction of scrap in your manufacturing facility.

It Will Reduce Your Labor Costs

Manual work requires more time and manpower, which in the end will cost you a lot. With far less setup time, CNC milling machines will help you reduce labor costs significantly. Milling machines finish a couple of days of manual work in only a few hours. Same as other automated CNC machines, the CNC milling machines require lower supervision. You can employ a single person to supervise the operation of any CNC machine.

Photo from Pexels

CNC Milling Translates To Improved Efficiency

Being designed with a non-stop performance, the CNC milling machine allows manufacturers to use them continually. The only thing is that the machine needs to be switched off on occasions for maintenance and repair. The machine also requires no warm-up time, which means it can be operated anytime.

Because most software-controlled precision milling machines allow idea simulation, there is no need to build or use a prototype. Once the machine has the software programmed into it, it can produce countless replicas with the exact same precision every time. CNC machines are five times faster than traditional machines, it is why they provide greater throughput.

Extreme Accuracy And Precision Of The Final Product Is Guaranteed

The accuracy and precision of CNC milling are still unmatched and superior to standard milling machines. CNC machines include advanced software and features which guarantee the accuracy of the milled piece. The CNC milling process can also ensure high positional accuracy and a high degree of repeatability.

Updated software and components parts are essentials that ensure productivity and part accuracy. Most software programs are simple to understand, and rookie operators can easily follow the manufacturer’s manual when using the machine for the first time.

It Allows For Versatility In The Production Process

Every manufacturer has to deal with many materials on a daily basis. CNC milling machines allow the manufacturers to shape and cut materials without losing on quality or efficiency. Since those machines enable working with many materials, machine operators are able to multitask and produce different parts at one time.

It Prolongs The Life Of The Tools

The utilization of preset tooling and other sophisticated techniques used in CNC milling machines reduces the downtime between batches. Since each function of the CNC milling machines is controlled by computer programs, the incorporated tools in the machine can be used at optimal speeds. That will result in longer tool life.

Photo by Daniel Smyth from Unsplash

CNC Milling Can Be Combined With Other Operations

With computer automation and engineers’ vision, CNC milling machines can mill almost anything imaginable. The CNC milling machines also allow for additional operations to be added to the milling process, which provides increased functionality.

For instance, a lathe could initially remove a mass of a part’s material, creating any required round turns. Then, the same part can be milled, with drilled holes, extra taps, etc. A sole operator controlling both mills in one chamber, or work center, can produce a complete part. Moreover, not having multiple operators and work centers raises efficiency.

CNC Milling Applications

One of the most frequently used machining processes is CNC Milling, including contour milling and plain milling that processes and taps parts. CNC milling is applicable to a wide variety of objects.

Flat Parts

Every surface is a plane or can be expanded into a plane. The large majority of objects processed on a CNC milling machine are flat parts. It’s also the simplest CNC milling part and can be produced just by two coordinate linkages of 3-axis machines.

Angled Parts

The parts, whose angle continually changes within the horizontal surface and the machining surface are called variable angle parts. It’s better to utilize the 4-axis or 5-axis controlled milling machine to process the parts with that kind of angle.

Curved Parts

The machining exterior of curved parts is all the time in point contact with the milling cutter. Curved parts are generally produced by a 3-axis CNC milling machine.

Final Words

Nowadays, CNC milling is widely used in manufacturing facilities throughout the globe. Companies benefit from the milling machines that use a computer to control the motion of one or more axes electronically. The advantages of CNC milling are huge, as you can see in the above-given examples, so don’t hesitate to utilize this CNC machining method in your production process.